Maelezo ya Bidhaa

Kisanduku na mirija inayotumika sana kwa ajili ya maendeleo ya mafuta na gesi, Kisanduku na mirija ni vipengele muhimu katika tasnia ya mafuta na gesi vinavyotumika kwa ajili ya uchimbaji na usafirishaji wa hidrokaboni (mafuta na gesi asilia) kutoka kwenye mabwawa ya chini ya ardhi hadi juu ya ardhi. Vina jukumu muhimu katika kuhakikisha usalama, uadilifu, na ufanisi wa shughuli za kuchimba visima na uzalishaji.

Mirija ni aina ya bomba linalotumika kuhamisha mafuta ghafi na gesi asilia kutoka kwenye safu ya mafuta au safu ya gesi hadi ardhini baada ya kuchimba visima kukamilika. Mirija huruhusu shinikizo linalotokana wakati wa mchakato wa uchimbaji. Mirija huzalishwa kwa njia sawa na kifuniko, lakini mchakato unaoitwa "upsetting" unahitajika pia ili kufanya bomba kuwa nene.

Kifuniko hutumika kulinda visima vilivyochimbwa ardhini kwa ajili ya mafuta. Vikitumika kama bomba la kuchimba visima, mabomba ya kizingiti cha visima vya mafuta pia huruhusu shinikizo la mvutano wa mhimili, kwa hivyo chuma chenye ubora wa juu na nguvu ya juu kinahitajika. Vizingiti vya OCTG ni mabomba makubwa yenye kipenyo ambayo yameunganishwa kwenye kisima.

Vipimo

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Kipimo cha 1, Kipimo cha 3, Kipimo cha 4, Kipimo cha 6, Kipimo cha 7, Kipimo cha 8, Kipimo cha 9. Kipimo cha 10, Kipimo cha 11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

Orodha ya Kisanduku cha Chuma cha ISO/API

| Leboa | Nje kipenyo D mm | Nominella mstari wingib, c Sheria na Masharti kilo/m | Ukuta unene t mm | Aina ya mwisho wa kumaliza | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Aina ya 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS PSB PSLB — — | PS PSB PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB PLB | — — — — PLB |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS PSLB PSLBE — — — — | PS PSLB PLB PLB PLB — — | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — — PLBE PLB PLB PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS PSLBE PSLBE | PS PSLB PLB PLB PLB | — — PLBE PLBE PLBE — — — — — — — | PLBE PLBE PLBE | PLBE PLBE PLBE P P P P P P P | PLBE PLBE PLBE | — — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | PSLB PSLBE — | PSLB PLB PLB — | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS PSLBE PSLBE — — — — — — — — — | — PS PLB PLB PLB PLB — — — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P | — — — PLBE PLBE PLBE PLBE PLBE — — — — — | — — — — — — PLBE PLBE — — — — — |

| Tazama maelezo mwishoni mwa jedwali. | ||||||||||||

| Leboa | Nje kipenyo D mm | Nominella mstari wingib, c Sheria na Masharti kilo/m | Ukuta unene t mm | Aina ya mwisho wa kumaliza | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Aina ya 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | PSLBE | PSLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB P P | PLBE PLBE PLBE PLB PLB PLB | PLBE PLB PLB PLB |

| 7-3/4 | 46.10 | 19,685 | 6,860 | 1,511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — PSLBE PSLBE — — — | PS PS PSLB PSLB PLB — — | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — — PLBE PLBE PLBE | — — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — PSLB PSLBE — — — — — — — — | — PSLB PSLB PLB PLB — — — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB P P P P | — — — PLBE PLBE PLBE PLB — — — — | — — — — PLBE PLBE PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | PSB PSBE PSBE | PSB PSB PSB PSB | PSBE PSBE | PSBE PSBE | PSBE PSBE PSBE PSB P P P | PSBE PSBE PSBE PSB | PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | PSB PSB PSB — — | PSB PSB PSB — — | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — PSB PSB PSB — | — PSB PSB PSB — | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — — PSB |

| Tazama maelezo mwishoni mwa jedwali. | ||||||||||||

| Leboa | Nje kipenyo D mm | Nominella mstari wingib, c Sheria na Masharti kilo/m | Ukuta unene t mm | Aina ya mwisho wa kumaliza | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Aina ya 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | PSB PSB P | PSB PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47,308 | 13,021 | 1,105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | PSL — — | PSLB PSLB PSLB | PSLB PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Mwisho tupu, S = Uzi mfupi wa duara, L = Uzi mrefu wa duara, B = Uzi wa kitako, E = Mstari uliokithiri. | ||||||||||||

| ♦ Lebo ni za taarifa na usaidizi katika kuagiza. ♦ Uzito wa mstari wa nominella, uliounganishwa na kuunganishwa (safu ya 2) huonyeshwa kwa taarifa pekee. ♦ Uzito wa vyuma vya kromiamu vya martensitiki (aina za L80 9Cr na 13Cr) ni tofauti na vyuma vya kaboni. Kwa hivyo, uzito ulioonyeshwa si sahihi kwa vyuma vya kromiamu vya martensitiki. Kipimo cha urekebishaji wa uzito cha 0,989 kinaweza kutumika. | ||||||||||||

| Lebo | Kipenyo cha nje D mm | Mstari wa mwisho usio na mshono wingi kilo/m | Unene wa ukuta t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

Orodha ya Mirija ya Chuma ya ISO/API

| Lebo | Nje kipenyo D mm | Mstari wa nominella wingia, b | Ukuta nene- uimara t mm | Aina ya mwisho wa kumalizac | |||||||||||

| Sio- kukasirika Sheria na Masharti kilo/m | Kiendelezi. kukasirika Sheria na Masharti kilo/m | Integ. kiungo kilo/m | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Sheria na Masharti | EU Sheria na Masharti | IJ | H40 | J55 | L80 | N80 Aina ya 1, Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.900 1.900 1.900 1.900 1.900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI PNUI PU — — | PI PNUI PU — — | — PNUI PU P P | — PNUI PU — — | — PNUI PU P P | — PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN PNU | PN PNU | PN PNU PNU P PU | PN PNU PNU — — | PN PNU PNU P PU | PN PNU PNU P PU | PNU PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | PNU — — | PNU — — | PNU PNU PNU PU | PNU PNU PNU — | PNU PNU PNU PU | PNU PNU PNU PU | PNU PNU PNU — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN PNU PN — — — — | PN PNU PN — — — — | PN PNU PN PNU P P P | PN PNU PN PNU — — — | PN PNU PN PNU P P P | PN PNU PN PNU P P P | — PNU — PNU — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | — 11.00 — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | PNU | PNU | PNU P P P P P P | PNU — — — — — — | PNU P P P P P P | PNU P P P P P P | |||

| P = Mwisho tupu, N = Uzio usio na usumbufu na uliounganishwa, U = Uzio wa nje uliounganishwa na uliounganishwa, I = Kiungo jumuishi. | |||||||||||||||

| ♦ Uzito wa mstari wa kawaida, nyuzi na kiunganishi (safu ya 2, 3, 4) huonyeshwa kwa taarifa pekee. ♦ Uzito wa vyuma vya kromiamu vya martensitiki (aina za L80 9Cr na 13Cr) ni tofauti na vyuma vya kaboni. Kwa hivyo, uzito ulioonyeshwa si sahihi kwa vyuma vya kromiamu vya martensitiki. Kipimo cha urekebishaji wa uzito cha 0,989 kinaweza kutumika. ♦ Mirija isiyo na msukosuko inapatikana kwa kutumia viunganishi vya kawaida au viunganishi maalum vya bevel. Mirija ya nje inayoweza kusukosuko inapatikana kwa kutumia viunganishi vya kawaida, maalum vya bevel, au maalum vya uwazi. | |||||||||||||||

Kiwango na Daraja

Kisanduku na mirija Daraja za Kawaida:

API 5CT J55,K55,L80, N80,P110, C90, T95, H40

Kizingo cha API 5CT na ncha za bomba la mirija:

(STC) Kifuniko kifupi cha uzi wa duara

(LC) Kifuniko kirefu cha uzi wa mviringo

(BC) Kifuniko cha uzi cha kitako

(XC) Kizingiti chenye mstari wa juu sana

(NU) Mirija isiyo na usumbufu

(EU) Mirija ya nje iliyopasuka

(IJ) Mirija jumuishi ya viungo

Kizingiti na bomba vinapaswa kuwasilishwa kulingana na miunganisho iliyo hapo juu na kiwango cha Viwango vya API5CT / API.

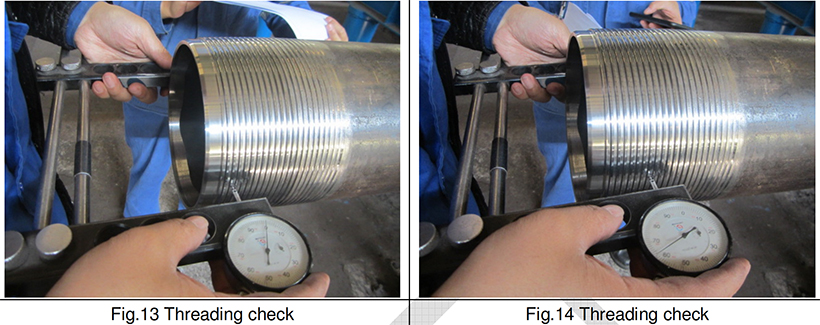

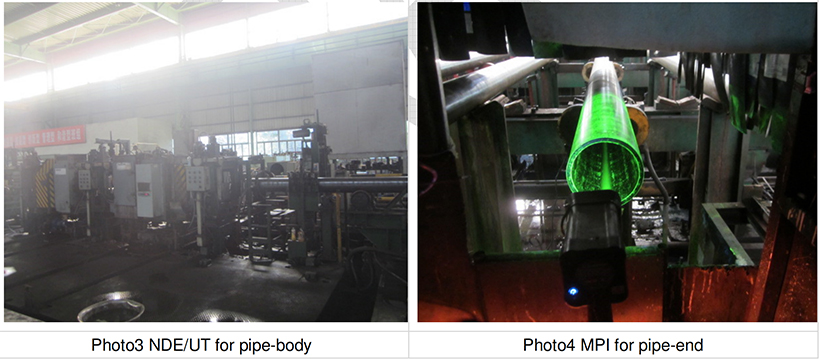

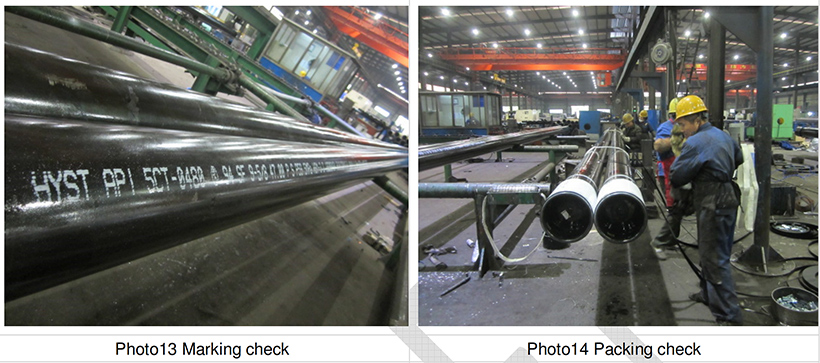

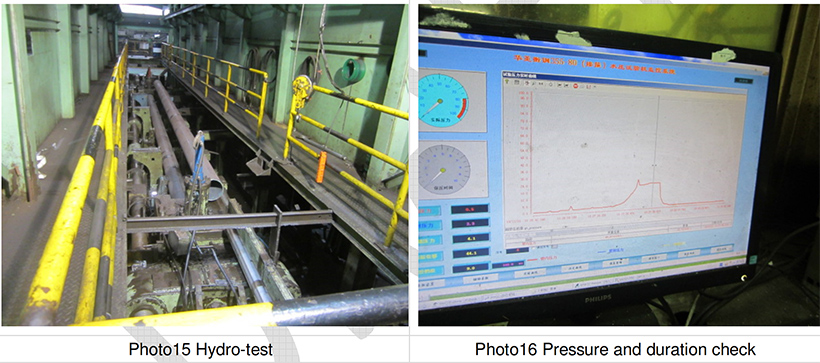

Udhibiti wa Ubora

Ukaguzi wa Malighafi, Uchambuzi wa Kemikali, Jaribio la Mitambo, Ukaguzi wa Kuona, Jaribio la Mvutano, Ukaguzi wa Vipimo, Jaribio la Kupinda, Jaribio la Kunyoosha, Jaribio la Athari, Jaribio la DWT, Jaribio la NDT, Jaribio la Maji Tuli, Jaribio la Ugumu…..

Kuweka alama, Kuchora kabla ya kuwasilisha.

Ufungashaji na Usafirishaji

Mbinu ya kufungasha mabomba ya chuma inahusisha kusafisha, kuweka makundi, kufungasha, kufungasha, kuweka lebo, kuweka kwenye godoro (ikiwa ni lazima), kuweka kwenye vyombo, kuweka kwenye vifungashio, kufunga, kusafirisha, na kufungua. Aina tofauti za mabomba ya chuma na vifaa vyenye mbinu tofauti za kufungasha. Mchakato huu kamili unahakikisha kwamba mabomba ya chuma yanasafirishwa na kufika mahali yanapoenda katika hali nzuri, tayari kwa matumizi yaliyokusudiwa.

Matumizi na Utumiaji

Mabomba ya chuma hutumika kama uti wa mgongo wa uhandisi wa kisasa wa viwanda na ujenzi, na kusaidia matumizi mbalimbali yanayochangia maendeleo ya jamii na uchumi duniani kote.

Mabomba na vifaa vya chuma ambavyo Womic Steel ilitengeneza vilitumika sana kwa ajili ya mafuta, gesi, mafuta na mabomba ya maji, pwani/pwani, miradi ya ujenzi wa bandari na ujenzi, uchimbaji, miradi ya ujenzi wa Chuma, urundikaji na madaraja, pia mirija ya chuma ya usahihi kwa ajili ya uzalishaji wa roli za kusafirishia, n.k.