Utangulizi:

API 5L ni vipimo vya kawaida vilivyoanzishwa na Taasisi ya Petroli ya Marekani (API) kwa mabomba ya chuma yasiyo na mshono na yaliyounganishwa yanayotumika katika mifumo ya usafirishaji ndani ya viwanda vya mafuta na gesi asilia. Womic Steel, mtengenezaji anayeongoza wa mabomba ya mstari wa API 5L, hutoa aina mbalimbali za bidhaa zinazokidhi viwango na vipimo mbalimbali. Makala haya yanatoa ulinganisho wa kina wa muundo wa kemikali, sifa za mitambo, na viwango vya upimaji kwa viwango tofauti vya API 5L, PSL1 na PSL2 katika aina tatu za mabomba: ERW (Electric Resistance Welded), LSAW (Longitudinal Submerged Arc Welded), na SMLS (Seamless).

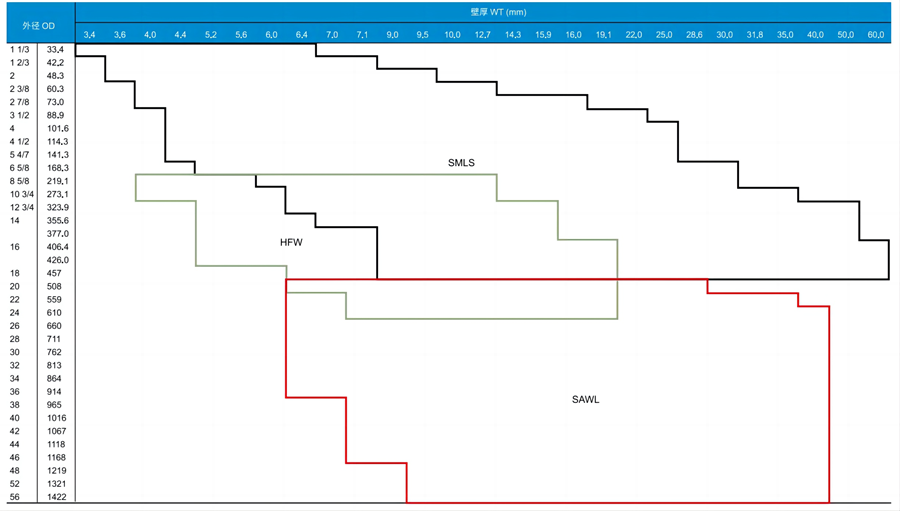

Uwezo wa Uzalishaji na Umbali:

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Kiwango cha chini mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| SMLS | B | X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Uvumilivu wa Kipenyo cha Nje

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| SPISHI YA API SO 3183 | D<60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm≤D≤168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3mm | +0.5%/-0.5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0.75%/-0.75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0.5%/-0.5% | ± 2.0mm | ± 1.6mm | ≤1.5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Kumbuka: D ni kipenyo cha nje cha bomba.

Uvumilivu wa Unene wa Ukuta

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| SPISHI YA API ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12.5% | ||

| - | 5.0mm | +10%/-10% | ||

| - | 15.0mmst<25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm≤t<30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t<37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

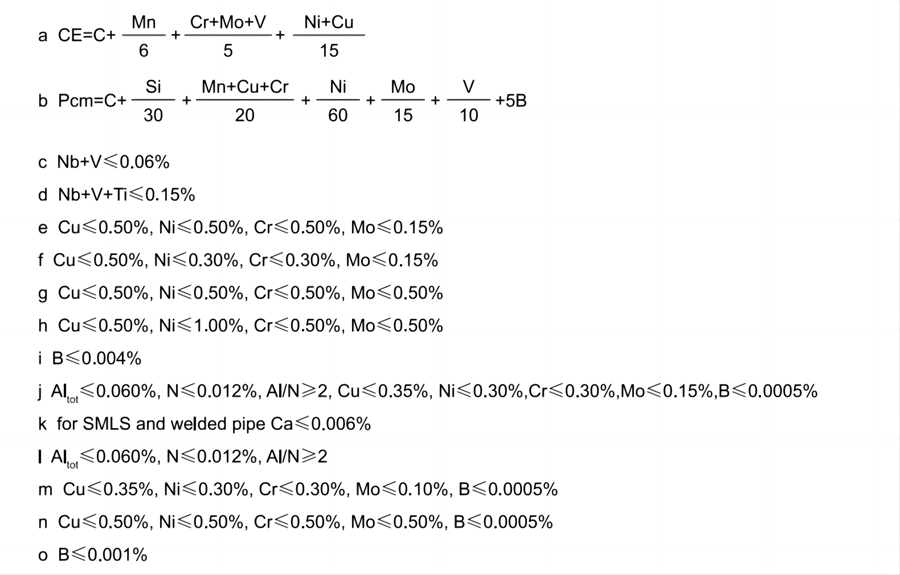

Uchambuzi wa Kemikali

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | Pcm | 备注 |

| upeo | upeo | upeo | upeo | upeo | upeo | upeo | upeo | upeo | upeo | |||||

| API SPEC 5L | 无缝管 | PSL1 | L210 au A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 au B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c,d,e,o | |||

| L290 au X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L320 au X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 au X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 au X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 au X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 au X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L485 au X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | L245N au BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | c,f,o | ||

| L290N au X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N au X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N au X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N au X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N au X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Kama ilivyokubaliwa | d,g,o | ||||

| L245Q au BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L290Q au X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q auX46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 au ×52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L390Q au X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415Q au X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450Q au X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485Q au X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555Q au X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Kama ilivyokubaliwa | h, mimi | ||||

| 酸性服 | L245NS au BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c,d,j,k | ||

| L290NS au X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| L320NS au X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | dj,k | |||

| L360NS au X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| L245QS au BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L290QS au X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L320QS au X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| L360QS au X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| L390QS au X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| L415QS au X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | dj,k | |||

| L450QS au X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| L485QS au X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | CEa | Pcm | 备注 |

| upeo | upeo | upeo | upeo | upeo | upeo | upeo | upeo | upeo | upeo | |||||

| AP|SPEC 5L | 无缝管 | 海上服 | L245NO au BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c,d,I,m |

| L290NO au X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO au X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d, mimi, m | |||

| L360NO au X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d, mimi | |||

| L245QO au BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L290QO au X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L320QO au X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| L360QO au X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,I,n | |||

| L390QO au X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,I,n | |||

| L415QO au X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,I,n | |||

| L455QO au X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,I,n | |||

| L485Q0 au X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| L555QO au X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Kama ilivyokubaliwa | d,I,n | ||||

| 焊管 | PSL1 | L245 au B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 auX42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 auX46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 au X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 auX56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 auX60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 au X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 au X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | 1245M au BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| L290M au X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320M au X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L360M au X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L390M au X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M au X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450M au X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485M au X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555M au X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CEa | Pcm | 备注 |

| upeo | upeo | upeo | upeo | upeo | upeo | upeo | upeo | upeo | upeo | |||||

| API SPEC 5L | 焊管 | 酸性服 | L245MS au BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| L290MS au X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| L320MS au X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| L360MS au X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| L390MS au X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| L415MS au X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| L450MS au X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| L485MS au X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | dj,k | |||

| 海上服 | L245MO au BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| L290MO au X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| L320MO au X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Mimi, m | |||

| L360MO au X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,I,n | |||

| L390MO au X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO au X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,I,n | |||

| L450MO au X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,I,n | |||

| L485MO au X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| L555MO au X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,I,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPEC 5L | PSL1 | L210 au A | Kiwango cha chini | 210 | 335 | a |

| 335 |

| L245 au B | Kiwango cha chini | 245 | 415 | a |

| 415 | ||

| L290 au X42 | Kiwango cha chini | 290 | 415 | a |

| 415 | ||

| L320 au X46 | Kiwango cha chini | 320 | 435 | a |

| 435 | ||

| L360 au X52 | Kiwango cha chini | 360 | 460 | a |

| 460 | ||

| L390 au X56 | Kiwango cha chini | 390 | 490 | a |

| 490 | ||

| L415 au X60 | Kiwango cha chini | 415 | 520 | a |

| 520 | ||

| L450 au X65 | Kiwango cha chini | 450 | 535 | a |

| 535 | ||

| L485 au X70 | Kiwango cha chini | 485 | 570 | a |

| 570 | ||

| PSL2 | L245N au BN | Kiwango cha chini | 245 | 415 | a |

| 415 | |

| Kiwango cha juu | 450 | 655 |

| 0.93 |

| |||

| L290N au X42N | Kiwango cha chini | 290 | 415 | a |

| 415 | ||

| Kiwango cha juu | 495 | 655 |

| 0.93 |

| |||

| L320N au X46N | Kiwango cha chini | 320 | 435 | a |

| 435 | ||

| Kiwango cha juu | 525 | 655 |

| 0.93 |

| |||

| L360N au X52N | Kiwango cha chini | 360 | 460 | a |

| 460 | ||

| Kiwango cha juu | 530 | 760 |

| 0.93 |

| |||

| L390N au X56N | Kiwango cha chini | 390 | 490 | a |

| 490 | ||

| Kiwango cha juu | 545 | 760 |

| 0.93 |

| |||

| L415N au X60N | Kiwango cha chini | 415 | 520 | a |

| 520 | ||

| Kiwango cha juu | 565 | 760 |

| 0.93 |

| |||

| L450Q au X65Q | Kiwango cha chini | 450 | 535 | a |

| 535 | ||

| Kiwango cha juu | 600 | 760 |

| 0.93 |

| |||

| L485Q au X70Q | Kiwango cha chini | 485 | 570 | a |

| 570 | ||

| Kiwango cha juu | 635 | 760 |

| 0.93 |

| |||

| L555Q au X80Q | Kiwango cha chini | 555 | 625 | a |

| 625 | ||

| Kiwango cha juu | 705 | 825 |

| 0.93 |

| |||

| L625M au X90M | Kiwango cha chini | 625 | 695 | a |

| 695 | ||

| Kiwango cha juu | 775 | 915 |

| 0.95 |

| |||

| L690M au X100M | Kiwango cha chini | 690 | 760 | a |

| 760 | ||

| Kiwango cha juu | 840 | 990 |

| 0.97 |

| |||

| L830M au X120M | Kiwango cha chini | 830 | 915 | a |

| 915 | ||

| Kiwango cha juu | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPEC 5L | 酸性服 | L245NS au BNS | Kiwango cha chini | 245 | 415 | a |

| 415 |

| Kiwango cha juu | 450 | 655 |

| 0.93 |

| |||

| L290NS au X42NS | Kiwango cha chini | 290 | 415 | a |

| 415 | ||

| Kiwango cha juu | 495 | 655 |

| 0.93 |

| |||

| L320NS au X46NS | Kiwango cha chini | 320 | 435 | a |

| 435 | ||

| Kiwango cha juu | 525 | 655 |

| 0.93 |

| |||

| L360NS au X52NS | Kiwango cha chini | 360 | 460 | a |

| 460 | ||

| Kiwango cha juu | 530 | 760 |

| 0.93 |

| |||

| L390QS au X56QS | Kiwango cha chini | 390 | 490 | a |

| 490 | ||

| Kiwango cha juu | 545 | 760 |

| 0.93 |

| |||

| L415QS au X60QS | Kiwango cha chini | 415 | 520 | a |

| 520 | ||

| Kiwango cha juu | 565 | 760 |

| 0.93 |

| |||

| L450QS au X65QS | Kiwango cha chini | 450 | 535 | a |

| 535 | ||

| Kiwango cha juu | 600 | 760 |

| 0.93 |

| |||

| L485QS au X70QS | Kiwango cha chini | 485 | 570 | a |

| 570 | ||

| Kiwango cha juu | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO au BNO | Kiwango cha chini | 245 | 415 | a | - | 415 | |

| Kiwango cha juu | 450 | 655 |

| 0.93 |

| |||

| L290NO au X42NO | Kiwango cha chini | 290 | 415 | a |

| 415 | ||

| Kiwango cha juu | 495 | 655 |

| 0.93 |

| |||

| L320NO au X46NO | Kiwango cha chini | 320 | 435 | a |

| 435 | ||

| Kiwango cha juu | 520 | 655 |

| 0.93 |

| |||

| L360NO au X52NO | Kiwango cha chini | 360 | 460 | a |

| 460 | ||

| Kiwango cha juu | 525 | 760 |

| 0.93 |

| |||

| L390QO au X56QO | Kiwango cha chini | 390 | 490 | a |

| 490 | ||

| Kiwango cha juu | 540 | 760 |

| 0.93 |

| |||

| L415QO au X60QO | Kiwango cha chini | 415 | 520 | a | - | 520 | ||

| Kiwango cha juu | 565 | 760 |

| 0.93 |

| |||

| L450QO au X65QO | Kiwango cha chini | 450 | 535 | a | - | 535 | ||

| Kiwango cha juu | 570 | 760 |

| 0.93 |

| |||

| L485Q0 au X70Q0 | Kiwango cha chini | 485 | 570 | a |

| 570 | ||

| Kiwango cha juu | 605 | 760 |

| 0.93 |

| |||

| L555QO au X80QO | Kiwango cha chini | 555 | 625 | a |

| 625 | ||

| Kiwango cha juu | 675 | 825 |

| 0.93 |

Kumbuka: a: Urefu wa chini kabisa kwa kutumia mlinganyo ufuatao: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | D<1422mm | D=1422mm | |

| ≤L415 au X60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| >L415 au X60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L450 au X65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L485 au X70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

Kumbuka: (1) Thamani zilizo kwenye jedwali zinafaa kwa sampuli ya kawaida ya ukubwa kamili.

(2) Thamani iliyo ndani ya mabano ni thamani ya chini kabisa, mabano ya nje ni thamani ya wastani.

(3) Joto la Jaribio: 0°C.

Viwango vya Upimaji:

Mabomba ya mstari ya API 5L yaliyotengenezwa na Womic Steel yanafanyiwa majaribio makali ili kuhakikisha yanakidhi viwango vya ubora wa juu zaidi. Viwango vya majaribio ni pamoja na:

Uchambuzi wa Kemikali:

Muundo wa kemikali wa chuma huchambuliwa ili kuthibitisha kwamba inakidhi mahitaji ya vipimo vya API 5L.

Uchambuzi wa kemikali hufanywa kwa kutumia spektromita ya usomaji wa moja kwa moja ili kubaini kwa usahihi muundo wa elementi wa chuma.

Upimaji wa Mitambo:

Sifa za kiufundi kama vile nguvu ya mavuno, nguvu ya mvutano, na urefu hupimwa ili kuhakikisha zinakidhi mahitaji yaliyoainishwa.

Upimaji wa mitambo hufanywa kwa kutumia mashine ya kupima mvutano ya tani 60 ili kupima nguvu na udukivu wa chuma.

Upimaji wa Hidrostati:

Upimaji wa hidrostatic unafanywa ili kuangalia uadilifu wa bomba na kuhakikisha linaweza kuhimili mahitaji ya shinikizo la matumizi yake yaliyokusudiwa.

Mabomba hujazwa maji na kukabiliwa na shinikizo, huku muda wa majaribio na viwango vya shinikizo vikibainishwa na viwango vya API 5L.

Upimaji Usioharibu (NDT):

Mbinu za NDT kama vile upimaji wa ultrasonic (UT) na upimaji wa chembe za sumaku (MT) hutumika kugundua kasoro au kutoendelea yoyote kwenye bomba.

UT hutumika kutambua kasoro za ndani, huku MT ikitumika kugundua kasoro za uso.

Upimaji wa Athari:

Upimaji wa athari hufanywa ili kutathmini uimara wa chuma kwenye halijoto ya chini.

Jaribio la athari la Charpy hutumika sana kupima nishati ya athari inayofyonzwa na chuma.

Upimaji wa Ugumu:

Upimaji wa ugumu unafanywa ili kutathmini ugumu wa chuma, jambo ambalo linaweza kuonyesha nguvu na ufaa wake kwa matumizi maalum.

Jaribio la ugumu la Rockwell mara nyingi hutumika kupima ugumu wa chuma.

Uchunguzi wa Muundo wa Mikrofoni:

Uchunguzi wa muundo mdogo hufanywa ili kutathmini muundo wa nafaka na ubora wa jumla wa chuma.

Darubini ya metallurgiska hutumika kuchunguza muundo mdogo wa chuma na kutambua kasoro zozote.

Kwa kuzingatia viwango hivi vikali vya upimaji, Womic Steel inahakikisha kwamba mabomba yake ya mstari ya API 5L yanakidhi mahitaji ya ubora wa juu zaidi na hutoa utendaji wa kuaminika katika matumizi mbalimbali ya viwanda.

Mchakato wa Uzalishaji:

1. Mabomba ya Chuma Yasiyo na Mshono:

- Uchaguzi wa Malighafi: Vipande vya chuma vya mviringo vya ubora wa juu huchaguliwa kwa ajili ya utengenezaji wa mabomba ya chuma yasiyo na mshono.

- Kupasha joto na Kutoboa: Vipande vya ndani hupashwa joto hadi kiwango cha juu na kisha kutoboa ili kutengeneza ganda lenye uwazi.

- Kuviringisha na Kusawazisha: Kisha ganda lililotobolewa huviringishwa na kunyooshwa hadi kipenyo na unene unaohitajika.

- Matibabu ya Joto: Mabomba hufanyiwa michakato ya matibabu ya joto kama vile kufyonza au kurekebisha ili kuboresha sifa zao za kiufundi.

- Kumalizia: Mabomba hupitia michakato ya kumalizia kama vile kunyoosha, kukata, na ukaguzi.

- Upimaji: Mabomba hupitia majaribio mbalimbali, ikiwa ni pamoja na upimaji wa hidrostatic, upimaji wa ultrasonic, na upimaji wa mkondo wa eddy, ili kuhakikisha ubora wake.

- Matibabu ya Uso: Mabomba yanaweza kupakwa au kutibiwa ili kuzuia kutu na kuboresha mwonekano wake.

- Ufungashaji na Usafirishaji: Mabomba hufungashwa kwa uangalifu na kusafirishwa kwa wateja.

2. Mabomba ya Chuma ya LSAW (Longitudinal Inayozama Tao)

- Maandalizi ya Sahani: Sahani za chuma zenye ubora wa juu huandaliwa kwa ajili ya utengenezaji wa mabomba ya LSAW.

- Uundaji: Mabamba huundwa katika umbo la "U" kwa kutumia mashine ya kupindika kabla.

- Kulehemu: Bamba zenye umbo la "U" kisha huunganishwa pamoja kwa kutumia mchakato wa kulehemu wa safu iliyozama.

- Upanuzi: Mshono uliounganishwa hupanuliwa hadi kipenyo kinachohitajika kwa kutumia mashine ya ndani au nje ya kupanuliwa.

- Ukaguzi: Mabomba hufanyiwa ukaguzi kwa kasoro na usahihi wa vipimo.

- Upimaji wa Ultrasound: Mabomba hufanyiwa upimaji wa ultrasound ili kugundua kasoro zozote za ndani.

- Kupanua: Ncha za bomba zimepanuliwa kwa ajili ya kulehemu.

- Upako na Uwekaji Alama: Mabomba yanaweza kupakwa na kuwekwa alama kulingana na mahitaji ya mteja.

- Ufungashaji na Usafirishaji: Mabomba hufungashwa na kusafirishwa kwa wateja.

3. Mabomba ya Chuma ya HFW (Kulehemu kwa Masafa ya Juu):

- Maandalizi ya Koili: Koili za chuma huandaliwa kwa ajili ya utengenezaji wa mabomba ya HFW.

- Uundaji na Uunganishaji: Koili huundwa katika umbo la silinda na kisha huunganishwa kwa kutumia uunganishaji wa masafa ya juu.

- Kupasha joto kwa mshono wa kulehemu: Mshono wa kulehemu hupashwa joto hadi halijoto ya kulehemu kwa kutumia kupasha joto kwa uingizaji wa masafa ya juu.

- Ukubwa: Bomba lililounganishwa limeundwa kwa kipenyo na unene unaohitajika.

- Kukata na Kupasua: Bomba hukatwa kwa urefu unaotakiwa na ncha zake hupasuliwa kwa ajili ya kulehemu.

- Ukaguzi: Mabomba hufanyiwa ukaguzi kwa kasoro na usahihi wa vipimo.

- Upimaji wa Hidrostatic: Mabomba hupimwa kwa nguvu na uvujaji kwa kutumia upimaji wa hidrostatic.

- Upako na Uwekaji Alama: Mabomba yamepakwa na kuwekwa alama kulingana na mahitaji ya mteja.

- Ufungashaji na Usafirishaji: Mabomba hufungashwa na kusafirishwa kwa wateja.

Michakato hii ya uzalishaji wa kina inahakikisha ubora wa juu na uaminifu wa mabomba ya chuma yasiyo na mshono, LSAW, na HFW yaliyotengenezwa na Womic Steel, yakidhi mahitaji magumu ya viwanda mbalimbali.

Matibabu ya Uso:

Matibabu ya uso wa chuma cha bomba ni muhimu kwa kuboresha upinzani wake wa kutu na maisha ya huduma. Womic Steel hutumia mbinu mbalimbali za matibabu ya uso kulingana na mahitaji tofauti kutoka kwa wateja, ikiwa ni pamoja na:

1. Kuchovya kwa Moto: Bomba la chuma huingizwa kwenye zinki iliyoyeyushwa ili kuunda safu ya kinga ya aloi ya zinki-chuma, na kuongeza upinzani wake wa kutu. Kuchovya kwa Moto kunafaa kwa mabomba ya kawaida na yenye shinikizo la chini.

2. Mipako ya Kuzuia Kutu: Mipako ya kawaida ya kuzuia kutu ni pamoja na mipako ya epoxy, mipako ya polyethilini, na mipako ya polyurethane. Mipako hii huzuia kwa ufanisi oksidi na kutu kwenye uso wa bomba la chuma, na kuongeza muda wa matumizi yake.

3. Ulipuaji wa mchanga: Ulipuaji wa kasi ya juu hutumika kusafisha bomba la chuma, kuondoa kutu na uchafu kutoka kwenye uso, na kutoa msingi mzuri wa matibabu ya baadaye ya mipako.

4. Matibabu ya Mipako: Uso wa bomba la chuma unaweza kupakwa rangi zinazozuia kutu, rangi za lami, na mipako mingine ili kuongeza upinzani wake wa kutu, unaofaa kwa mabomba na mabomba ya chini ya ardhi katika mazingira ya baharini.

Mbinu hizi za matibabu ya uso hulinda chuma cha bomba kutokana na kutu na uharibifu, na kuhakikisha uaminifu na uimara wake katika mazingira mbalimbali magumu.

Ufungashaji na Usafirishaji:

Womic Steel huhakikisha ufungashaji salama na usafirishaji wa kuaminika wa chuma cha bomba, na kutoa chaguzi zinazobadilika ili kukidhi mahitaji mbalimbali ya wateja:

1. Mizigo Mikubwa: Kwa oda kubwa, chuma cha bomba kinaweza kusafirishwa kwa wingi kwa kutumia meli maalum za kubeba mizigo mikubwa. Chuma hupakiwa moja kwa moja kwenye sehemu ya kushikilia meli bila vifungashio, vinafaa kwa usafirishaji wa kiasi kikubwa kwa gharama nafuu.

2. LCL (Chini ya Mzigo wa Kontena): Kwa maagizo madogo, chuma cha bomba kinaweza kusafirishwa kama mizigo ya LCL, ambapo maagizo mengi madogo huunganishwa kwenye kontena moja. Njia hii ina gharama nafuu kwa kiasi kidogo na inatoa ratiba rahisi zaidi za uwasilishaji.

3. FCL (Mzigo Kamili wa Kontena): Wateja wanaweza kuchagua usafirishaji wa FCL, ambapo kontena kamili huwekwa wakfu kwa oda yao. Njia hii hutoa muda wa usafirishaji wa haraka na hupunguza hatari ya uharibifu wakati wa kushughulikia.

4. Usafirishaji wa Anga: Kwa maagizo ya haraka, usafirishaji wa anga unapatikana kwa ajili ya usafirishaji wa haraka. Ingawa ni ghali zaidi kuliko usafirishaji wa baharini, usafirishaji wa anga hutoa usafiri wa haraka na wa kuaminika kwa usafirishaji unaozingatia wakati.

Womic Steel huhakikisha kwamba usafirishaji wote umefungashwa vizuri ili kuzuia uharibifu wakati wa usafirishaji. Chuma kwa kawaida hufungwa kwa vifaa vya kinga na kufungwa kwenye makontena au kwenye godoro ili kuhakikisha uthabiti wakati wa usafirishaji. Zaidi ya hayo, kampuni inafanya kazi kwa karibu na washirika wa usafirishaji wanaoaminika ili kuhakikisha usafirishaji kwa wakati unaofaa na usimamizi mzuri wa vifaa.

Matukio ya Matumizi:

Mabomba ya mstari ya API 5L yanayozalishwa na Womic Steel hutumika sana katika tasnia ya mafuta na gesi asilia kwa ajili ya usafirishaji wa mafuta, gesi, na vimiminika vingine. Pia hutumika katika tasnia zingine mbalimbali kama vile usindikaji wa kemikali, uzalishaji wa umeme, na ujenzi.

Hitimisho:

Womic Steel ni mtengenezaji anayeaminika wa mabomba ya mstari wa API 5L, akitoa bidhaa zenye ubora wa juu zinazokidhi mahitaji magumu ya viwanda vya mafuta na gesi asilia. Kwa kuzingatia ubora, uaminifu, na kuridhika kwa wateja, Womic Steel inaendelea kuwa chaguo linalopendelewa kwa wateja duniani kote.

Muda wa chapisho: Machi-22-2024